The Towering Innovation of the Wind Industry

Transitioning the United States to clean energy in time to meet the Biden-Harris administration’s goals requires resolving some key financial and logistics issues. The wind industry is working to address these issues, particularly in the area of manufacturing and transportation of tall wind turbine towers.

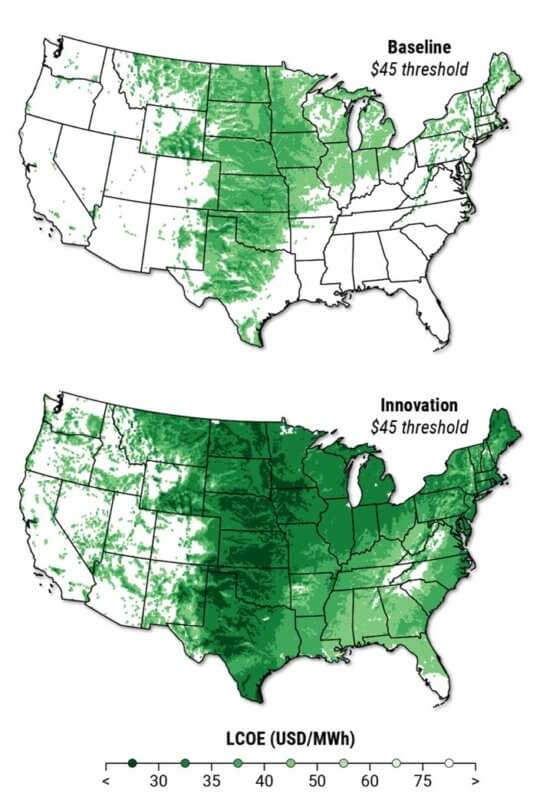

Taller land-based wind turbines can harness and generate more power than shorter ones, because they can access faster wind speeds at greater heights. More wind power can lead to greater profits and open the door to a major wind energy expansion across the nation (see Figure 1).

Figure 1: Estimated expanded geographic area at a reference cost of $45 per megawatt-hour for tall towers up to 160 meters, considering projected costs in 2030.

However, bigger wind turbine towers generally come with bigger price tags. The steel used to build them is costly. And transporting large towers ranges from difficult to impossible, due to size restrictions on bridges and highways. Technological innovation is necessary to eliminate these obstacles and increase the amount of wind energy available to the American people.

Enter American Clean Power member companies like Keystone Tower Systems Inc. and GE Renewables. The U.S. Department of Energy Wind Energy Technologies Office awarded these two companies a total of $10 million in 2019 and 2020 to develop manufacturing methods for tall tower construction and installation that could break down the financial and transportation barriers.

These companies are pioneering two distinct manufacturing techniques to achieve one objective: lower-cost on-site production of taller wind turbine towers, which could enable more towers in more U.S. locations.

Keystone Tower Systems Inc. uses a spiral-welding technique borrowed from the steel-pipeline industry to construct some of the tallest towers on the market. The first 2.98 megawatt wind turbine using a spiral-welded tower is expected to be installed later this year.

Keystone towers are up to twice as tall and made 10 times faster than conventional towers. They can be made on site or at factories that take up less space than other wind manufacturing facilities.. One of the cost-saving benefits of Keystone’s spiral-welding technique is that it uses less steel. Even with those savings, demand for steel will continue to rise with the expanded wind deployment necessary to meet President Biden’s climate and renewable energy objectives.

GE Renewables is using a 3-D printed concrete pedestal to manufacture tower bases with customizable heights that can be produced on-site, which, when coupled with standard steel tower sections, can reach over 140 meters. These innovations will help the wind industry overcome the transportation constraints currently hindering tall tower installations in the United States and lower construction costs.

With both companies developing processes that can support producing towers at project sites rather than at manufacturing facilities, the challenges of transporting tall towers—and the associated transportation-related emissions—could soon be problems of the past.

Keystone and GE Renewables are just two of the many examples of companies who are forging the path to an affordable clean energy future. Masterful problem-solving and creativity are elevating the wind power industry as a key player in the pursuit of economic and environmental stability.

See more of this industry innovation on display by attending ACP’s CLEANPOWER 2022 Conference and Exhibition in San Antonio from May 16 – 18, 2022. The 2022 U.S. Department of Energy Collegiate Wind Competition (CWC) will be occurring in conjunction with CLEANPOWER. The annual competition challenges interdisciplinary teams of undergraduate students from a variety of programs to offer a unique solution to a complex wind energy project using the multi-faceted elements and provides each student with real-world experience as they prepare to enter the wind industry workforce. Visit cleanpower.org/expo to learn more.

This is a guest blog post from Mike Derby, Program Manager, Wind Technology at the U.S. Department of Energy’s Wind Energy Technologies Office.