What’s the state of American wind power manufacturing?

Manufacturing may be a struggling part of the American economy, but not for the factories, workers and companies that build wind turbines.

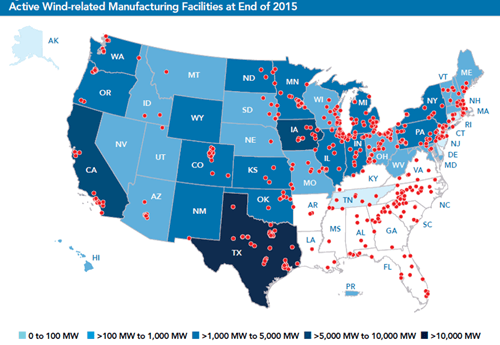

Over 500 factories build wind-related parts and materials in 43 states, making everything from major wind turbine components such as nacelles, blades, towers, and gearboxes, to internal components like bearings, slip rings, fasteners, and power converters. These facilities supported more than 25,000 manufacturing jobs in 2016. Overall, 100,000 U.S. wind jobs exist across all 50 states.

Wind energy manufacturing hot spots

Ohio boasts the highest number of wind-related manufacturing facilities with over 60 plants, followed by Texas (38), Illinois (35), North Carolina (27), and Michigan (26). Although much of the Southeast currently lacks wind farms, it’s a wind manufacturing hub, with more than 100 wind-related factories.

The U.S. wind industry supply chain includes eight utility-scale blade facilities, nine tower facilities, and four turbine nacelle assembly facilities. Last year, 88 percent of the wind capacity installed in the U.S. used a turbine manufacturer with at least one U.S. manufacturing facility. According to LBNL, the share of domestic manufacturing content for nacelle assembly exceeds 85 percent, while towers are between 80 to 85 percent. Blades and hubs also have strong domestic content, estimated between 50 to 70 percent.

All three of the top wind turbine manufacturers in the country, as a share of installed capacity, have domestic manufacturing facilities:

- U.S.-based GE Renewable Energy has a turbine manufacturing facility in Pensacola, Florida and a blade facility in New Orleans, Louisiana, as well as an advanced manufacturing research center in South Carolina. GE also recently acquired LM Wind Power, which has two large-scale blade facilities in Arkansas and North Dakota.

- Vestas has a turbine nacelle facility, tower facility, and two blade facilities in Colorado. Combined these four factories employ around 3,200 people.

- Siemens has a nacelle facility in Hutchinson, Kan. with about 360 employees, and a blade facility in Fort Madison, Iowa with about 600 employees.

Supply Chain Growth

However, it’s not just the major players that create manufacturing opportunities– wind energy has an expansive supply chain since each turbine contains over 8,000 parts. Wind-related manufacturers up and down the chain are expanding facilities and hiring more workers to meet growing U.S. wind industry demand. In the last year, at least nine companies expanded existing facilities or opened new ones. Some examples include:

- Last August, Vestas added 100,000 square feet of new production space and hired 350 new employees at their blade factories in Windsor and Brighton, Colorado. In January 2016, they sought an additional 100 employees.

- GRI Renewable Industries is currently building a new tower manufacturing plant in Amarillo, Texas, which they say will employ at least 300 people and make about 400 wind towers a year.

- LM Wind Power expanded its Little Rock Port Authority facility with a new 44,000 square foot warehouse and pre-molding facility in April 2016.

- Broadwind Energy is expanding its tower facility in Abilene, Texas that will increase annual tower production capacity by 30 percent.

- In May 2016, Jupiter Composites completed a 25,000 square foot expansion of its nacelle cover facility in Pensacola, Florida. Thanks to demand from GE’s nearby turbine facility, Jupiter Composites’ workforce grew from 28 to 250 employees in 18 months.

- Gearbox Express expanded its wind gearbox remanufacturing operations to a new 75,000 square foot facility in Mukwonago, Wisconsin in May 2016 to help meet wind industry demand. The new facility nearly doubles the size of their original building, and they plan to add another 30,000 square feet of manufacturing space to increase annual capacity to 400 gearboxes.

- In November 2015, MM Composite Inc. started operations at a new plant in Mount Pleasant, Iowa that makes composite components for Siemens wind turbine blades.

- In October 2016, PGTEX, a company that produces composite materials for wind and other industries, opened a manufacturing plant in El Paso, Texas – its first in North America. They plan to employ 150 people by 2020.

All of this means new job growth and an influx of economic development for local communities. America’s wind energy manufacturing sector is thriving, providing opportunities for well-paying careers that tens of thousands of U.S. workers and their families can count on, and these opportunities should continue to increase for years to come.